If your glass manufacturing operation is struggling with inefficient production planning, production delays, high scrap rates, or inefficient machine usage, you’re not alone. Many companies struggle to find a reliable way to optimize production planning, which can make or break their success.

Based on years of working closely with glass manufacturers, we’ve seen firsthand the recurring challenges that come with production planning. Through that experience, we’ve identified five proven best practices that consistently help streamline operations and reduce inefficiencies.

In this article, you’ll learn how to:

- Reduce material waste through smarter cutting strategies

- Eliminate bottlenecks with balanced machine scheduling

- Improve delivery performance by aligning production with customer deadlines

By the end, you’ll be able to spot inefficiencies in your current planning process and take action to create a smoother, more reliable glass production workflow.

The Challenges of Production Planning in Glass Processing and How to Solve Them

Before diving into solutions, it’s essential to understand the specific hurdles you face. Addressing these challenges effectively requires a clear strategy, along with the right tools.

If you manage glass production, you know that planning isn’t just about assigning tasks to machines. It’s a complex balancing act that involves:

- Precise timing: Each piece of glass must be processed in a strict order to avoid bottlenecks.

- Machine efficiency: Some machines have higher throughput than others, requiring careful workload balancing.

- Minimizing scrap: Cutting optimization must be done with precision to reduce waste.

- Sorting and sequencing: Mismanagement of sorting and sequencing leads to chaotic assembly and delays.

- Customer deadlines: Every miscalculation in planning jeopardizes delivery commitments.

Without a solid production planning strategy, glass manufacturers often face:

- Inefficiencies – Machines sit idle while waiting for the right glass pieces.

- High scrap rates – Poor cutting and nesting strategies waste material.

- Bottlenecks – One overloaded stage causes delays across the entire workflow.

- Last-minute chaos – Rush orders disrupt everything, causing overtime and stress.

But here’s the good news: with the right planning system, these inefficiencies can be minimized or eliminated. Now that we’ve identified the key challenges, let’s explore the best practices that can drive efficiency and eliminate these common pitfalls.

How Production Planning Drives Efficiency in Glass Manufacturing

Now that we understand the challenges of glass manufacturing, let’s explore the best practices proven to drive efficiency and solve common pain points in production planning.

1. Optimize sorting and assembly for a smoother workflow

Sorting plays a pivotal role in reducing delays and ensuring a smooth production flow. When glass pieces aren’t correctly sorted before assembly, production bottlenecks and misaligned cutting sequences create inefficiencies.

The solution:

Smart sorting optimizes cutting sequences, whether or not you have a dedicated sorting center.

If your factory has a sorting center:

- Cutting can be done in any order, maximizing material efficiency.

- The sorting center automatically reorders glass for seamless assembly.

- Handling errors are reduced, minimizing costly mistakes.

If you don’t have a sorting center:

- Pre-plan cutting sequences in advance to match final assembly order.

- Minimize manual re-sorting to reduce handling errors.

Key takeaway: The more flexible your cutting stage, the more efficient your material usage and sequencing will be—leading to a smoother and faster production process.

Once the sorting and sequencing are under control, it’s time to focus on cutting. It can minimize scrap and make the most of every glass. Let’s take a closer look at how cutting optimization enhances production.

2. Reduce scrap and improve yield with cutting optimization

Without an optimized cutting process, manufacturers waste expensive raw materials, increasing production costs and inefficiencies.

And yet, even the best cutting plan is useless if the required glass sheets aren’t available in stock when the job is scheduled to start. Planning without visibility into stock availability often results in delays or last-minute changes to cutting orders.

The solution:

A smart cutting optimization tool can drastically reduce scrap by improving material utilization — but it should also integrate with stock management systems.

- Group orders intelligently to maximize glass sheet usage.

- Use nesting techniques to reduce unnecessary offcuts.

- Check available inventory before scheduling cuts, and flag missing items early.

- Balance workloads across cutting stations to prevent overloading certain machines.

Even if you’re not using an automated optimization system, implementing manual nesting strategies and precise cutting plans, and checking stock ahead of time can still reduce waste significantly.

Key takeaway: Every 1% improvement in glass utilization directly impacts your bottom line.

If you want to learn more about cutting optimization, check out our article on the 7 key elements to consider to reduce scrap rate and maximize efficiency in glass processing.

Now that we’ve looked at cutting optimization, let’s explore how balancing machines can further enhance your efficiency.

3. Balance machine loads to prevent bottlenecks

Even with optimized cutting, production bottlenecks can occur if workloads are unevenly distributed across machines. Common issues include:

- Overloaded machines: Backlogs can create significant delays.

- Idle machines: Some machines remain underused while others are overloaded.

- Unplanned downtime: Machines break down from uneven wear and tear.

The solution:

Load balancing ensures that no single machine is overworked while others remain underutilized.

- Use an automated workload distribution system to evenly allocate tasks.

- Manually monitor production lines and adjust assignments to prevent bottlenecks.

- Prioritize urgent orders while keeping the workflow balanced.

Key takeaway: A balanced production line is a productive production line.

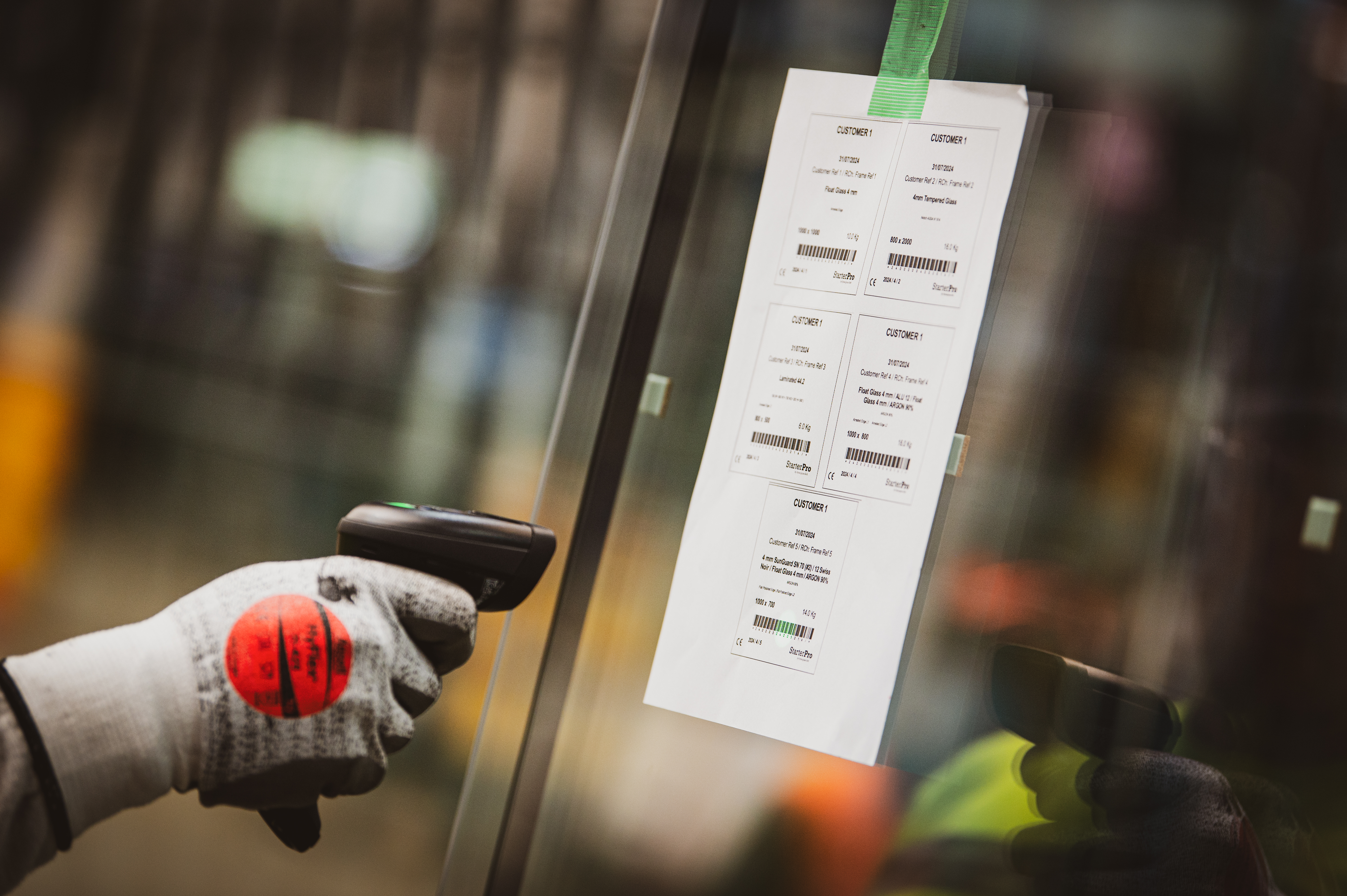

4. Use dynamic production monitoring to stay ahead of disruption

Staying ahead of potential disruptions is a game-changer in production planning. Production monitoring provides the visibility needed to act before small issues turn into large delays.

Why it’s important:

Monitoring production progress in real-time helps identify issues before they become crises. Delays and disruptions can result in missed deadlines and increased costs, but quick identification allows for immediate corrective action.

The solution:

A production monitoring system provides real-time insights to prevent disruptions.

- Live status updates allow managers to track production progress.

- Automated alerts notify personnel of delays or machine issues.

- Dynamic rescheduling helps adjust workflows in response to unexpected changes.

If you want to learn more about how ERP systems enhance production monitoring for glass processors, click here to read our blog article on the subject.

Key takeaway: The faster you react to issues, the less impact they’ll have on your overall production efficiency.

5. Backward scheduling: ensuring on-time deliveries

Planning backward from the delivery date helps prioritize tasks and ensures that your production process aligns with customer deadlines. This backward approach provides clarity and prevents costly mistakes.

Why the delivery date should drive planning:

The goal of production planning is to meet customer deadlines. Planning without considering the delivery date can result in premature orders (wasting space) or delays (leading to penalties).

The solution:

Backward scheduling ensures that each production step — including outsourced operations — is aligned with the final delivery date.

- Set the delivery date first and work backward to schedule internal and external phases.

- Include subcontractor lead times as fixed milestones in your schedule.

- Use scheduling tools to calculate precise start times for different processes.

- Identify potential delays early so they can be addressed before they cause disruptions.

Key takeaway: Start with the end goal—on-time delivery—and use backward scheduling techniques for a smoother, more predictable production process. This approach helps prioritize tasks effectively and ensures timely delivery, even without relying on specific systems.

Now that we’ve explored the best practices, it’s time to put them into action. Implementing these strategies with the right tools will help you streamline production, reduce delays, and boost efficiency.

Putting production planning into action

Optimizing production planning in glass manufacturing doesn’t have to be overwhelming. By implementing smart sorting, cutting optimization, and real-time monitoring, you can reduce waste and improve efficiency.

The key challenge is managing shifting priorities and delays, but with the right planning system, you can stay on track and meet deadlines consistently.

At Synerglass-Soft, we help businesses streamline their production processes and ensure timely deliveries. We’ve helped numerous companies improve their planning and operational efficiency.

Ready to put these best practices into action? Explore Symbiose’s modules today to optimize your production planning and track progress seamlessly. Start optimizing your production today!