If you’re still running your glass processing operations on a legacy, monolithic ERP, you’re probably dealing with slow updates, integration issues, costly customizations, and the constant fear that any change could break the system. You’re not alone — this is one of the biggest headaches we hear from production managers and IT leads in the industry.

Imagine trying to upgrade your smartphone by taking it apart and replacing the internal components, one by one, every few months. Sounds painful, right? Now imagine doing that with your entire ERP system — the one that manages your orders, production, stock, billing… everything. That’s pretty much your reality. But it doesn’t have to be.

At Synerglass-Soft, we’ve been there: years spent maintaining a monolithic ERP system, only to hit a wall when it comes to flexibility, growth, or stability. Shifting to a modular ERP is not just a technical upgrade — it’s a strategic move that gives you more control, less stress, and room to evolve.

In this guide, we’ll break down the full transition process in plain language, show you where to start, and how to modernize your ERP without disruption. Here’s what you’ll walk away with:

- A clear definition of modular ERP (with no fluff)

- A proven roadmap for a phased, low-risk transition

- Real-world examples and shortcuts to avoid common pitfalls

You don’t have to rip everything out. You just need the right first step — and that’s exactly what we’ll show you.

Before you begin: rethinking ERP mindset for a modular transition

Switching from a monolithic ERP to a modular system isn’t just about installing a new piece of software. It’s about rethinking how your business adapts to change. And that’s where many businesses get stuck.

In a monolithic setup, your ERP is like a massive machine — everything is interconnected, and if one cog breaks, the whole thing slows down. Updates become big risky projects, testing eats up time, and even the smallest change can cause a chain reaction of problems.

Modular ERP systems are designed to expect and absorb change. You gain the ability to update, test, and grow individual parts of your system independently — without triggering a domino effect.

This mindset shift is key: Instead of asking “how do we replace everything?” the real question is, “how do we evolve, one module at a time?”

Let’s look at where that evolution begins.

Step #1: identify core business processes before moving to modular ERP

Before you even look at software options, pause and map out your critical operations. These are the areas that drive value for your business and can’t afford to slow down during a transition.

For most glass processors, these include:

- Order management

- Production planning

- Inventory control

- Billing and invoicing

In a modular ERP, each of these can be handled by its own focused module. That means even if replacing one module causes a disruption, the adjustment will be minimal, controlled, and far less risky than in a monolithic system.

Think of it like building with LEGO blocks.

If your invoicing process is outdated, you don’t need to tear down the whole system. You just replace that one block and the rest keeps working.

Once you’ve clarified these business-critical functions, it’s time to assess your current setup’s flexibility.

Step #2: evaluate your current ERP’s API integration capabilities

Next, evaluate whether your existing ERP can interact with modular solutions — especially via APIs.

Ask:

- Does our system support APIs?

- Is our data clean and structured enough for integration?

- What manual workflows need to be automated?

Most modern modular ERPs rely on APIs to connect different tools and features. These allow systems to “talk to each other” without risk. Even better, APIs come with documentation — giving your IT team clarity, control, and the ability to safely develop their own enhancements without depending entirely on a vendor.

If you can answer these questions confidently, you’re in a good position to move forward.

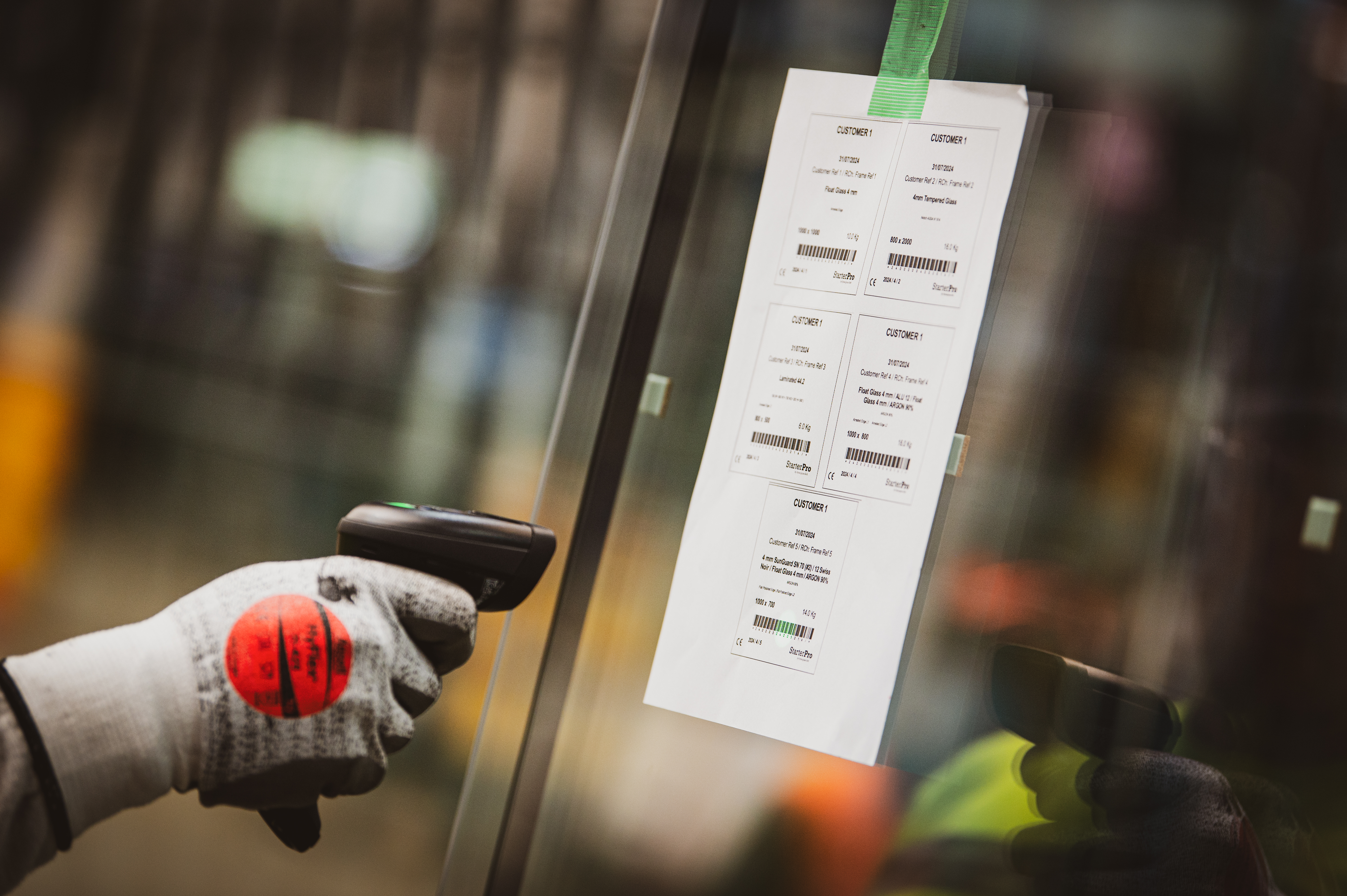

Step #3: launch a pilot ERP module to kick off your modular transition

Rather than replacing everything at once, start with a single high-impact function.

Choose a process that:

- Is painful today

- Can run independently

- Will show measurable improvement fast

For many glass processors, that might be inventory tracking or production planning. Starting here gives your team a manageable first step and builds confidence in the new system’s potential.

Once that first module is working, and your team is used to it, you’ll be ready to build on that momentum.

Step #4: transition safely with a phased modular ERP rollout

Unlike replacing parts of a car engine while it’s running, modular ERP adoption doesn’t require ripping anything out.

The idea is to run the new system alongside your existing ERP. One module at a time. Each module handles just one slice of your business. As it proves reliable and your team is comfortable, you can begin deactivating the old system’s equivalent function.

For example:

- Implement inventory as a standalone module

- Introduce live production scheduling

- Add real-time invoicing tools

This phased adoption minimizes risk and avoids overwhelming your team. Each success builds trust and momentum for the next step — without disrupting operations.

Think of it more like building a second home next door and moving in room by room, rather than remodeling the one you’re living in all at once.

Step #5: test and optimize each ERP module before expanding

Traditional ERP upgrades used to be dramatic — scheduled three times a year with weeks of manual testing and a high chance of something breaking.

Modular systems take a different approach. With automatic testing built in — often using a test pyramid strategy — most issues are caught before they even reach your users.

Updates are smaller, faster, and easier to reverse if needed. Even better, if a bug does appear, it’s usually contained within a single module. The rest of your system stays online and stable.

This modular isolation makes it safer and smarter to evolve without fear.

Step #5: train your team for confident modular ERP adoption

ERP transitions often fail because people don’t feel equipped to use the new system. That’s why ease of use — and good training — matter just as much as good tech.

In a well-designed modular ERP, activating a new module should feel like using a smartphone app:

- Click to test

- Evaluate it in real time

- Keep or cancel based on usefulness

Some systems even allow clients to activate modules independently. That’s especially useful for companies with internal IT teams or automation goals.

And when ERP platforms are designed with real UX expertise — not just functionality — they’re easier to adopt across your teams, devices, and accessibility needs.

Key business benefits of switching to modular ERP

So what do you actually gain from all of this? Here’s what businesses experience after moving to modular ERP:

- Continuous updates — no more big-bang releases

- Customizable architecture — choose what fits, ignore what doesn’t

- Faster innovation — small changes delivered regularly

- Resilient structure — one bug won’t bring everything down

- Greater control — APIs and self-service for internal IT teams

It’s not just software. It’s peace of mind, performance, and a platform you can actually grow with.

Final thoughts on modernizing ERP in glass processing

If you’ve been stuck with a legacy ERP system that makes every update a nightmare, you’re not alone — and you’re not out of options either. You now have a clear, phased roadmap to modernize without the disruption or risk that usually comes with major system changes.

Remember, the biggest fears we hear — fear of downtime, overwhelming change, or spiraling costs — don’t apply when you switch to a modular system the right way. This doesn’t have to be another “big bang” upgrade.

At Synerglass-Soft, we didn’t just build modular ERP software — we lived the pain that made it necessary. We’ve helped dozens of glass processors modernize their systems while keeping their teams confident and their business running.

Your next step is simple: Book a chat with our team to see where modular ERP could start working for you — one module at a time, with no pressure to commit to everything at once.