Introducing new technology into your manufacturing team sounds exciting — until you hit the reality of resistance, confusion, and frustration.

What looked like a smart upgrade turns into a slow-motion mess: operators avoid the system, supervisors fall back on old habits, and deadlines slip as people fumble through something they don’t trust or understand.

If you’ve ever felt like your tech rollout was harder than it should be, you’re not imagining it.

Poor adoption is one of the most common (and costly) failures in manufacturing.

At Synerglass-Soft, we’ve helped hundreds of glass manufacturing t eams go through digital transformations. We’ve seen the struggles up close — the false starts, the team pushback, the “great on paper” tools that never quite get used.

The good news?

Tech adoption doesn’t have to feel like an uphill battle — if you focus on the people first, not just the tools.

In this article, you’ll learn exactly how to:

- Involve your team early to build ownership and avoid surprise resistance

- Show clear, real-world benefits to get buy-in

- Deliver effective, practical training that builds confidence

- Keep momentum alive through positive reinforcement

- Create a safe learning culture where growth — not perfection — is the goal

By the end, you’ll walk away with a clear plan to make your next tech rollout smoother, faster, and far more successful.

Why tech adoption fails (and how you can avoid the common traps)

Before we dive into the five strategies, it’s important to understand why tech adoption so often goes wrong in manufacturing.

It’s rarely because the technology itself is bad.

More often, it’s because the rollout forgets the most important part of any business: the people.

When employees feel left out, overwhelmed, or scared of failure, even the best systems will gather dust.

But when they feel involved, supported, and confident, change becomes not just possible — it becomes exciting.

That’s what these five strategies are all about.

They’ll help you focus on what matters most: making the transition feel natural, manageable, and (believe it or not) even rewarding for your team.

5 key strategies for driving tech adoption on the factory floor

Let’s walk through the key steps that make the biggest difference when introducing new technology to manufacturing teams.

1. How to get your manufacturing team ready for new technology

Getting the rollout right starts before the rollout even happens.

Let’s talk about the first big step: making sure your team feels part of the change from the very beginning.

Answer: Involve your team early — way earlier than you think.

One of the fastest ways to create resistance is by dropping new tech on people out of nowhere. Nobody likes feeling blindsided.

Instead, bring your team into the conversation from the start.

- Ask them: “What’s slowing you down right now?”

- Let them test-drive options early (even if it’s just a demo).

- Show them that their feedback actually shapes decisions.

When people feel heard, they feel ownership. And when they feel ownership, they’re much more likely to champion the change instead of fighting it.

Quick tip:

Create a small “Tech Ambassador” group — real users from the shop floor — and let them help lead the rollout.

2. How to show the real benefits of new technology to manufacturing teams

Once you’ve involved your team early, the next challenge is helping them actually want to use the new system.

This is where clear, personal communication makes all the difference.

Answer: Always connect the tech to real, daily problems they care about.

It’s easy for leadership to see the big picture: faster reporting, better KPIs, more transparency.

But your team cares about their day-to-day.

Show them how the technology will:

- Save time on repetitive tasks or paperwork

- Reduce waste by minimizing human error or missed steps

- Increase output by simplifying tracking, reporting, or planning

- Prevent downtime by giving better visibility into job status or equipment readiness

Real-life example:

Instead of saying, “We’re improving data flow,” say, “No more wasting 20 minutes every day chasing misplaced production orders for glass cutting jobs.”

If the benefits aren’t obvious to them, adoption will stall.

3. How to train your team for successful tech adoption

Of course, knowing the benefits isn’t enough — your team needs to feel confident using the tool itself.

Training can either build that confidence… or destroy it if handled poorly.

Answer: Make learning part of the workday — not homework.

No one wants to stay late or study a confusing manual at home after a 10-hour shift.

Training should happen:

- During normal working hours

- In small, practical chunks

- With hands-on practice, not just PowerPoints

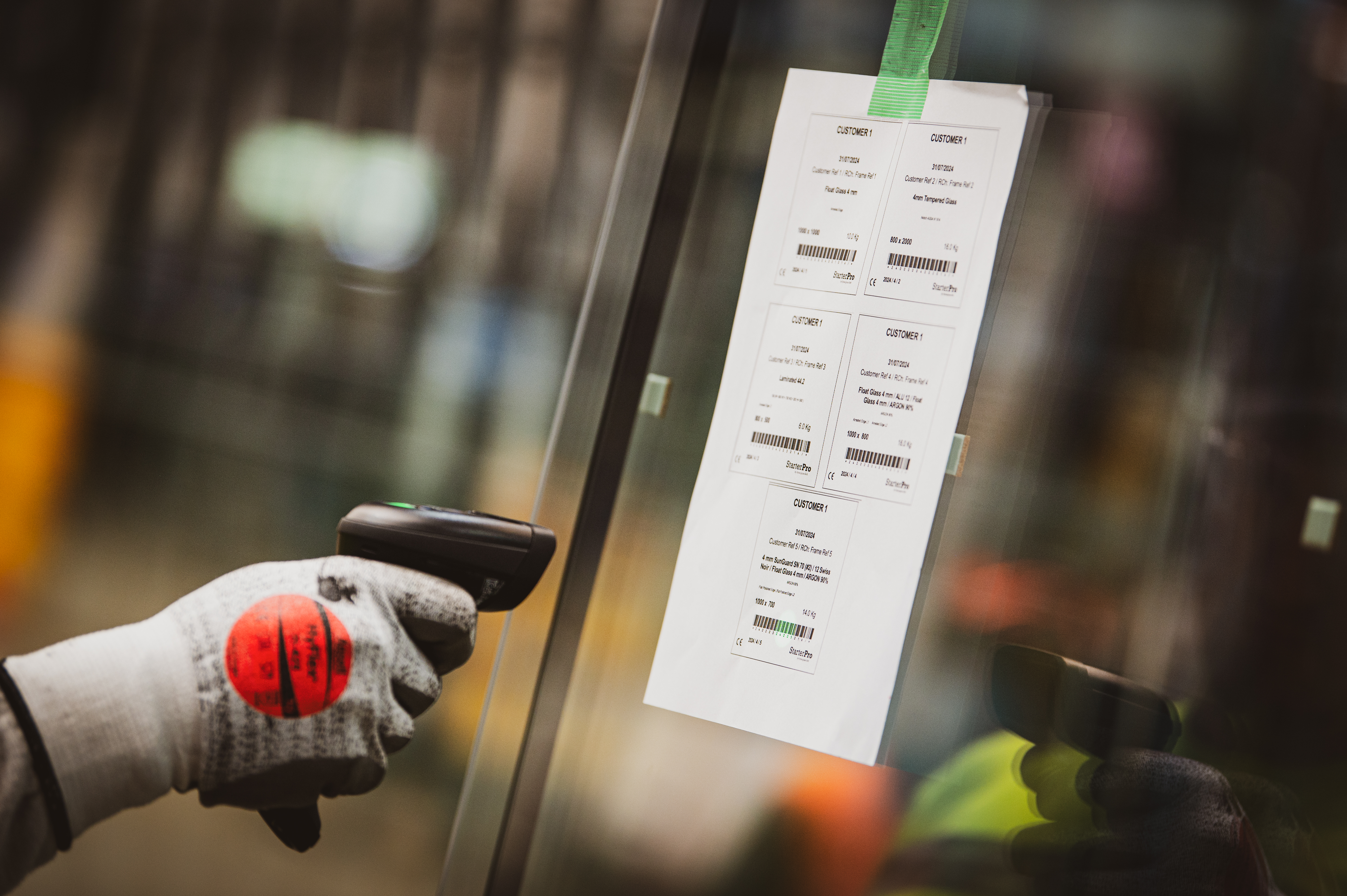

For example, if they’re learning to use a tool like SynerTracker, have operators practice scanning barcodes directly on delivery racks during their regular shift.

Or, if they’re getting familiar with a production planning system, let them update job statuses on production screens as part of their normal workflow.

Mistakes during training? Totally normal. Celebrate them as signs of real learning, not failures.

Pro tip:

Pair up your early adopters with people who are struggling — peer-to-peer learning feels safer and less intimidating than formal sessions.

4. How to keep tech rollouts moving forward on the factory floor

Even with good training, momentum can fizzle out if wins aren’t recognized.

Here’s how to keep the positive energy rolling after the first few steps.

Answer: Celebrate every small win — loudly and publicly.

The first time someone successfully uses the new system?

The first time a full day runs smoothly with the new process?

Celebrate it.

- Shout it out in team meetings

- Send a quick thank-you email

- Give a small reward (even something like a free coffee voucher)

Positive reinforcement works better than pressure every time.

It creates a snowball effect — people see others succeeding and start thinking, “Hey, maybe I can do this too.”

5. How to build a learning culture that embraces tech change

Finally, no matter how well you prepare and celebrate, real adoption only sticks if people feel safe trying, failing, and learning.

Let’s finish by talking about the culture you need to build.

Answer: Create a culture where struggling is expected — and totally OK.

Learning anything new is messy.

If your team feels like every mistake will be punished or judged, they’ll shut down.

Instead, tell them up front:

- “You’re supposed to have questions.”

- “You’re expected to need help.”

- “Nobody gets it 100% right on day 1.”

When people know they’re safe to struggle, they actually learn faster — and with a lot less stress.

Final thoughts: you don’t just need new tools — you need a new approach

You now know what causes most tech rollouts to fail — and how to prevent that from happening in your factory.

If your team has ever pushed back, struggled with training, or ignored a new tool altogether, you’re not alone. These are common (and solvable) problems — and the five strategies you’ve just learned can turn things around.

Your next step? Let’s work together to plan a tech adoption strategy that fits your team, your timeline, and your goals. Whether you’re launching something new or still recovering from a rollout gone sideways, Synerglass-Soft can help you get it right.

We’ve guided hundreds of manufacturing teams through successful digital transitions — and we’d love to help you do the same.

👉 Let’s talk about your next move.